Table of Contents

For global manufacturers and construction professionals, securing a reliable Wood PVC Film Supply involves a constant tug-of-war: balancing cost efficiency with high-end aesthetics. Traditional materials often force an uncomfortable compromise. Solid wood is notoriously unstable and prohibitively expensive, while entry-level laminates frequently fail to meet the visual and tactile standards required by modern design. Today, B2B buyers, architectural engineers, and project managers are under immense pressure to deliver durable, visually striking interiors on tighter budgets and accelerated schedules.

Wood grain PVC decorative film has emerged as the definitive answer to these industry-wide challenges. As a high-performance surface material, it bridges the gap between the organic beauty of nature and the resilience of synthetic engineering. By replicating the intricate textures of timber while offering superior resistance to environmental stressors, this material allows manufacturers to scale production without sacrificing quality.

In this comprehensive guide, we explore the technical composition, strategic advantages, and manufacturing excellence behind premium PVC wood grain films. From detailed performance metrics to navigating the global supply chain, this article serves as a strategic resource for making informed procurement decisions that drive profitability and project success.

Unveiling Wood PVC Film: Composition, Benefits, and Superiority

The Multi-Layered Engineering of PVC Decorative Film

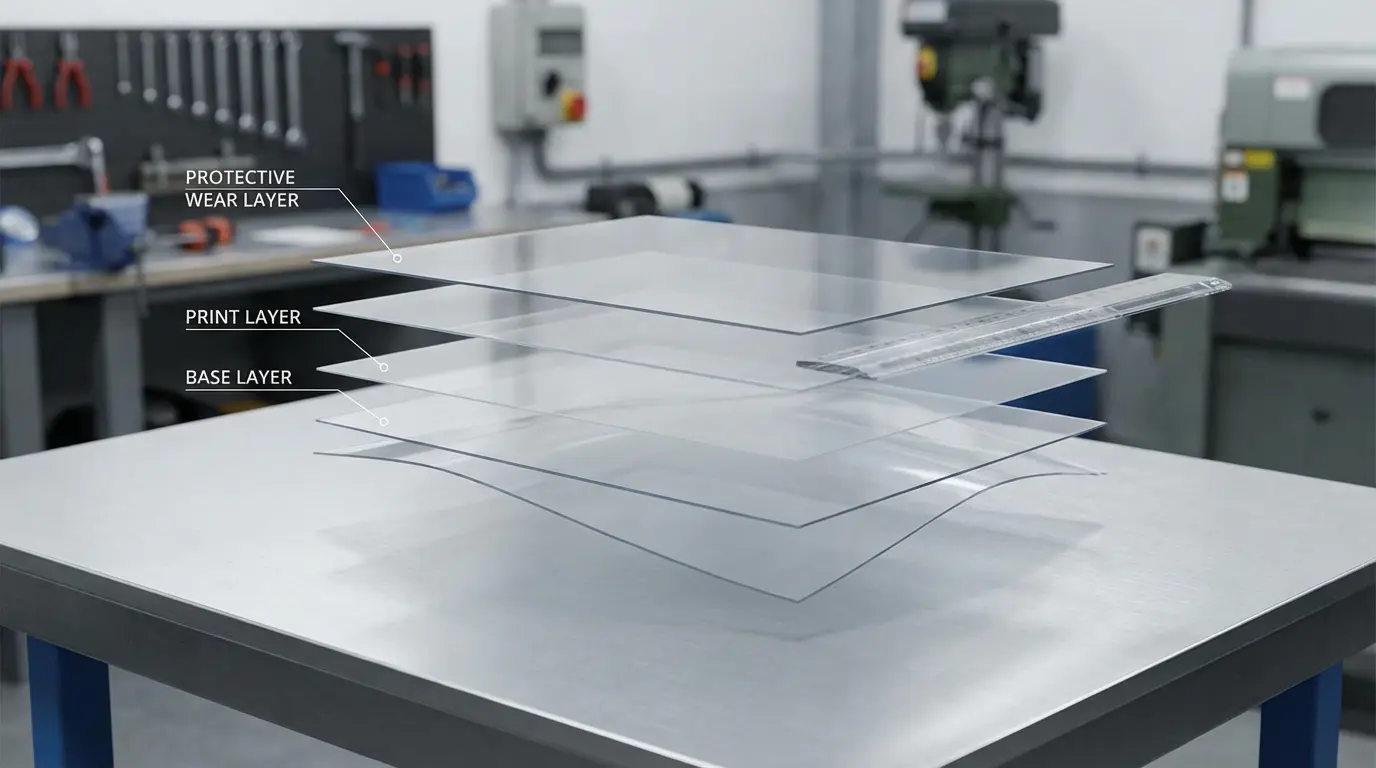

To evaluate the suitability of wood PVC film for industrial applications, one must understand its structural integrity. This is not merely a sheet of plastic; it is a sophisticated, multi-layered composite engineered for longevity and processability. At its core lies the base layer, formulated from high-grade PVC resin with a relative density typically ranging between 1.3 and 1.7 g/cm³. This specific density ensures the film possesses the necessary substance to adhere smoothly to substrates without bubbling or tearing during application.

Above the base sits the precision-printed decorative layer. Using advanced rotogravure printing, this layer achieves high-definition wood grain patterns that mimic natural timber species with exceptional fidelity. The structure is capped by a transparent wear layer, often reinforced with polyurethane (PU) or similar protective coatings. This engineering provides critical tensile strength—ranging from 10 to 25 MPa—allowing the film to stretch around complex corners during vacuum pressing without rupturing. With an elongation at break measuring between 200% and 400%, the material offers the flexibility required for profile wrapping and 3D membrane pressing.

Performance Benchmarks: PVC vs. Traditional Wood Materials

When stacked against traditional wood veneers or melamine papers, PVC film demonstrates clear superiority in both durability and maintenance. According to EN 438-2.10 standards, high-quality printed decors must withstand a minimum of 175 revolutions at the initial wear point. This resistance ensures that furniture surfaces retain their pattern integrity even under frequent abrasion—a non-negotiable requirement for office desktops and commercial cabinetry.

For B2B buyers, scratch resistance is another critical metric. Testing under EN 438-2.25 protocols reveals that premium PVC films achieve a Rating of 3 at a force of 2.0N. Under significant pressure, the surface shows only a slight change in gloss or color, whereas real wood veneer would likely suffer deep, permanent gouges requiring expensive refinishing. Furthermore, PVC film is non-porous and hydrophobic. It eliminates the need for periodic oiling or varnishing, significantly reducing the total cost of ownership for the end-user compared to solid wood.

Environmental Compliance and Sustainability

Modern manufacturing demands adherence to strict environmental standards, and advanced PVC films are engineered to meet these global expectations. Leading manufacturers now utilize formulations that drastically reduce Volatile Organic Compounds (VOC) emissions, contributing to healthier indoor air quality. These low-VOC films are instrumental for projects aiming for certifications such as LEED or GREENGUARD, making them a viable choice for schools and healthcare facilities.

Beyond emissions, chemical safety is paramount. Reputable Wood PVC Film Supply partners ensure their products are fully compliant with REACH and RoHS regulations, certifying the absence of hazardous heavy metals and toxic substances. Additionally, the thermoplastic nature of PVC allows for recyclability. Waste generated during the lamination process can often be re-processed, and the finished product supports the longevity of the furniture, delaying the entry of bulk items into landfills compared to less durable paper-based laminates.

Structure of Wood PVC Film Supply

Strategic Advantages for B2B Projects: Performance & Aesthetics

Validated Durability: Meeting International Standards

For large-scale B2B projects, relying on technical data is safer than relying on marketing claims. The durability of wood PVC film is validated through rigorous testing. Aside from wear resistance, the material’s softening temperature—typically between 80°C and 85°C—ensures stability during transport and storage in non-climate-controlled warehouses. For application, the material remains stable until decomposition begins at approximately 170°C, provided adequate stabilizers are used.

Fire safety is another non-negotiable aspect of commercial construction. High-quality PVC films boast a Limiting Oxygen Index (LOI) of ≥ 40. This indicates the material is difficult to ignite and does not support combustion in normal atmospheric conditions. When applied to appropriate substrates, these films help composite panels achieve building material classifications such as EN 13501-1 Class B-s1,d0. This classification signifies very limited contribution to fire, minimal smoke production, and no flaming droplets, giving architects the confidence to specify these materials for high-rise interiors and public corridors.

Visual Engineering: Texture and Optical Precision

The aesthetic value of wood PVC film is no longer secondary to its function; it is a primary selling point. Manufacturers utilize diverse embossing technologies to cater to varied market tastes. "Synchronized embossing" (EIR) aligns the physical texture perfectly with the printed grain, creating a tactile experience indistinguishable from real wood. "Deep embossing" offers a rustic, raw timber feel, while "Super-matt" finishes absorb light to create a modern, sophisticated look that hides fingerprints.

These textural variations allow furniture factories to offer broad product lines without changing their core substrate materials. A single production line using MDF boards can produce distinct collections—from "Scandinavian Minimalist" using light oak matte film to "Classic Luxury" using dark walnut high-gloss film—simply by changing the PVC roll. This versatility enables B2B buyers to react swiftly to design trends without the logistical nightmare of sourcing different species of real wood veneers, which vary wildly in color and grain consistency between batches.

Cost Efficiency and ROI Analysis

The financial argument for switching to a Wood PVC Film Supply is compelling. While solid wood represents the highest cost tier, wood veneer is generally 30-60% less expensive. PVC film provides even greater savings, often costing a fraction of veneer while eliminating secondary processing steps. Real wood requires sanding, staining, sealing, and top-coating—labor-intensive processes that introduce bottlenecks and quality control variables.

PVC film comes pre-finished. Once laminated, the part is ready for assembly. For a large-scale hotel project requiring 500 wardrobes, eliminating the finishing stage can reduce the production cycle by weeks and cut labor costs by 20-30%. The Return on Investment (ROI) is realized not just in raw material savings, but in increased throughput and reduced rejection rates. Unlike wood, which may warp or crack leading to waste, PVC film offers near 100% yield utilization, maximizing the profitability of every square meter purchased.

Climate Adaptability: From Humid Tropics to Arid Deserts

One of the critical failures of natural wood in global projects is its reaction to humidity. In regions like Southeast Asia, where humidity fluctuates drastically, solid wood and veneers absorb moisture, leading to swelling and delamination. Conversely, in the arid climate of the Middle East, wood can dry out and fracture. PVC film is inherently impervious to moisture.

Case studies in tropical climates demonstrate that furniture wrapped in high-quality PVC film retains its dimensional stability even in non-air-conditioned environments. The hydrophobic nature of the polymer prevents water ingress into the substrate (provided edges are sealed), making it the superior choice for bathroom vanities and kitchen cabinetry in humid zones. This reliability reduces post-installation warranty claims for contractors, protecting both their reputation and their bottom line.

Wood PVC Film Supply durability comparison

Versatile Applications: Transforming Furniture & Interior Spaces

Revolutionizing Furniture Manufacturing

In the realm of furniture production, wood PVC film is the workhorse of modern cabinetry. Its high elongation at break (200-400%) makes it uniquely suited for vacuum membrane pressing. This process allows the film to stretch over the complex contours of routed MDF doors, covering the face and edges in a single seamless operation. This eliminates the need for edge banding, which is often the weak point where moisture enters and delamination begins.

For wardrobe doors, office desks, and kitchen units, this "3D wrapping" capability allows for designs that include recessed panels, chamfered edges, and intricate grooves—styles that are incredibly difficult and costly to achieve with high-pressure laminates (HPL) or veneers. Furthermore, the consistency of the film ensures that a kitchen cabinet door produced in January will perfectly match a replacement drawer front produced in December, a consistency that natural wood cannot guarantee.

Commercial Interiors: Durability Meets Design

Commercial spaces such as hotels, hospitals, and retail environments demand surfaces that can withstand heavy traffic and aggressive cleaning regimes. Wood PVC film is extensively used for wall cladding, elevator interiors, and ceiling baffles. In healthcare settings, the non-porous surface of PVC film prevents the growth of bacteria and mold, and its chemical resistance allows it to withstand industrial disinfectants without fading or degrading.

Designers for retail chains utilize these films to create consistent brand environments across multiple locations. Whether it is a coffee shop chain requiring a specific "rustic oak" look or a tech store needing "sleek minimalist ash," the film ensures brand identity is maintained identically in every store, regardless of location. The ease of installation—often applied to lightweight substrates like gypsum or foam board—accelerates fit-out times, allowing businesses to open their doors sooner.

Architect and Designer Perspectives

Feedback from the architectural community highlights the design freedom offered by PVC films. Architects appreciate the ability to specify "exotic" wood grains—such as ebony or rosewood—without the ethical concerns or exorbitant costs associated with harvesting endangered species. The film provides the visual opulence of rare timbers in a sustainable, mass-producible format.

Moreover, the shortening of project timelines is a frequently cited benefit. Prefabricated wall panels wrapped in PVC film can be installed rapidly using dry construction methods, avoiding the dust and fumes associated with on-site painting or varnishing. This "pre-finished" advantage is crucial for renovation projects in occupied buildings, such as hotel refurbishments, where minimizing downtime is directly linked to revenue.

Elevating Residential Real Estate

In the competitive residential market, developers use high-end wood PVC finishes to increase perceived value. Luxury apartment projects often feature "soft-touch" matte PVC finishes on built-in joinery, mimicking the feel of expensive lacquered wood. These tangible details influence buyer perception, positioning the property in a higher bracket.

Successful implementations are seen in modular housing and build-to-rent sectors. Here, the durability of the film protects the asset owner's long-term investment. A rental property fitted with PVC-wrapped joinery will require significantly less maintenance and fewer replacements over a 10-year period compared to one fitted with painted or veneered surfaces, directly impacting the yield of the real estate portfolio.

Wood PVC Film Supply in kitchen application

Manufacturing Excellence & Quality Control: Ensuring Premium Supply

Precision Manufacturing Processes

The journey of a premium Wood PVC Film Supply begins with the calendering process. Raw PVC resin, mixed with plasticizers, stabilizers, and pigments, is heated and passed through a series of heavy rollers. This process flattens the mixture into a film of precise thickness. The control of roller temperature and speed is critical; deviations here can lead to variations in the film's density and mechanical properties.

Following base film production, the printing stage utilizes high-fidelity rotogravure cylinders. These cylinders are engraved with microscopic cells that hold ink, transferring the wood grain pattern onto the film. The final stage is lamination and embossing, where the wear layer is bonded, and the texture is pressed into the surface while the material is still pliable. Automated tension control systems ensure the film is wound onto rolls without stretching, preserving the pattern's geometry.

Rigorous Quality Certification

Trustworthy manufacturers operate under ISO 9001 quality management systems. Beyond this, specific product certifications are vital. The EN 13501 fire safety classification is tested in accredited laboratories, ensuring the chemical formulation reacts predictably to heat. Compliance with REACH standards requires rigorous supply chain auditing to trace every chemical additive, ensuring no Substances of Very High Concern (SVHC) are present.

Batch consistency is monitored using spectrophotometers to measure color values (Lab coordinates) against a master standard. A Delta E tolerance of less than 1.0 is typically maintained, ensuring the human eye cannot detect color differences between rolls produced months apart. This level of control is essential for B2B buyers who rely on repeatable results for long-running product lines.

Raw Material Integrity

The quality of the final film is dictated by the quality of the inputs. Premium manufacturers source PVC resin with a consistent K-value (molecular weight), which influences the film's strength and processing temperature. Stabilizers are selected not just for heat resistance (preventing decomposition below 170°C) but also for UV stability, preventing yellowing over time.

Evaluation of suppliers for inks and adhesives is equally stringent. Only light-fast inks that resist fading under UV exposure are utilized. The lamination adhesives must possess high bond strength to prevent delamination of the layers under the heat and vacuum pressure of the end-user's manufacturing process. Every incoming batch of raw material undergoes viscosity, moisture, and purity testing before entering the production floor.

Manufacturing process of Wood PVC Film Supply

Navigating the Supply Chain: A Guide for B2B Procurement

Evaluating Supplier Competency

When selecting a partner for Wood PVC Film Supply, B2B buyers must look beyond price. Key evaluation metrics include production capacity—can the factory scale up if your order volume doubles? Lead time is critical; a standard lead time of 15-20 days is competitive. Minimum Order Quantity (MOQ) varies; some factories require 3,000 meters per color, while others offer stock programs with lower MOQs for popular designs.

Technical support is an often-overlooked differentiator. A superior supplier will offer guidance on the optimal settings for your membrane press or wrapping machine (e.g., suggesting the ideal activation temperature for their specific adhesive backing). This consultative approach helps reduce waste during your initial production runs.

Global Sourcing Dynamics

The market is divided between European suppliers, known for trend-setting designs and premium pricing, and Asian suppliers, particularly in China, who offer a balance of quality and cost-efficiency. Modern Asian factories have largely closed the technology gap, utilizing German and Japanese machinery to produce films that rival European standards at a more competitive price point.

For global buyers, understanding these dynamics allows for a "China Plus One" or a hybrid strategy. You might source ultra-premium, trend-heavy films from Europe for a flagship collection, while utilizing high-volume, cost-effective Asian supply for core product lines.

Logistics and Import Strategy

Shipping heavy rolls of PVC film requires careful logistics. Films are typically packed in foam and cardboard, placed on pallets, and shrink-wrapped to prevent moisture ingress during sea freight. It is vital to ensure the supplier uses "suspended packaging" for sensitive high-gloss films to prevent pressure marks.

Customs classification (HS Codes) for PVC film generally falls under Chapter 39 of the Harmonized System. Buyers should verify current tariff rates and anti-dumping duties applicable to their specific country. Partnering with a freight forwarder experienced in chemical/plastic imports can streamline the clearance process and avoid costly demurrage charges at the port.

Risk Mitigation: The Sampling Protocol

Never commit to a full container load without a rigorous sampling protocol. Request A4 samples for color approval, but more importantly, request a roll for trial production. Test the film on your specific machinery. Does it bond correctly? Does the grain stretch acceptably at the corners? Does the color shift under your factory lighting?

Conducting "cross-hatch" adhesion tests and exposure tests (placing the finished part in a humidity chamber) will reveal any compatibility issues between the film and your adhesive or substrate. This small upfront investment in testing prevents the disastrous scenario of a product recall.

Logistics of Wood PVC Film Supply

Future Outlook: Innovations Driving Wood PVC Film Forward

Surface Technology Breakthroughs

The future of wood PVC film lies in functional performance. We are seeing the emergence of "self-healing" coatings, where micro-scratches can be repaired simply by applying thermal heat (like a cloth and an iron). Anti-fingerprint (AFP) technologies are becoming standard for matte finishes, utilizing nano-coatings to prevent oils from adhering to the surface.

Antimicrobial properties are also being integrated directly into the wear layer, using silver ion technology to inhibit bacterial growth. This innovation is particularly relevant for the post-pandemic world, driving demand in the healthcare and hospitality sectors.

The Green Revolution: Bio-Based PVC

Sustainability is driving R&D into bio-based PVC formulations. Manufacturers are experimenting with replacing petroleum-based plasticizers with bio-plasticizers derived from soy or linseed oil. These "green" films offer the same mechanical properties as traditional PVC but with a significantly lower carbon footprint. This evolution will be crucial for suppliers aiming to service the growing market of "Net Zero" building projects.

Expanding Horizons: Smart and Modular Construction

As the construction industry shifts toward off-site manufacturing and modular building, the demand for pre-finished materials will explode. Wood PVC film is perfectly positioned to serve this sector. We anticipate its integration into smart home surfaces—films that are conductive or transparent to capacitive touch signals, allowing furniture surfaces to act as controls for lighting or audio systems, blending technology seamlessly into the wood aesthetic.

Future innovations in Wood PVC Film Supply

Frequently Asked Questions

Q1: What are the cost and time advantages of Wood PVC Film compared to traditional wood veneer?

A: Wood PVC film is typically 30-50% more cost-effective than wood veneer. The primary savings come from eliminating finishing processes; PVC film is pre-finished, requiring no sanding, staining, or varnishing. This can reduce production cycles by days or even weeks, significantly lowering labor costs and increasing factory throughput.

Q2: How can I ensure the Wood PVC Film I purchase meets international safety standards?

A: Always request technical data sheets (TDS) and certification documents from the supplier. Look for ISO 9001 for quality management, and specific reports for REACH (chemical safety) and RoHS compliance. For fire safety, ask for EN 13501 test reports. Reputable suppliers will provide third-party verification for these standards.

Q3: Is Wood PVC Film durable enough for high-humidity or high-traffic areas?

A: Yes. PVC is inherently hydrophobic, making it immune to the moisture absorption that damages wood. High-quality films with a wear layer meeting EN 438 standards (≥ 175 revolutions) are highly resistant to abrasion. This makes them ideal for bathroom vanities in humid climates and commercial surfaces in hotels or offices.

Q4: Do you offer customization for specific colors, textures, or functional properties?

A: Yes, most professional factories offer OEM/ODM services. We can match specific wood grains from physical samples and adjust the embossing depth or gloss level. We can also formulate films with specific functional additives, such as cold-crack resistance or anti-bacterial coatings, to meet your project's unique requirements.

Conclusion

In the evolving landscape of interior design and furniture manufacturing, Wood PVC Film Supply represents more than just a material choice—it is a strategic asset. By combining the warm, organic aesthetics of wood with the industrial resilience of PVC, this material solves the age-old conflict between beauty, durability, and budget.

From its robust multi-layered composition and validated fire and wear resistance to its versatility in vacuum pressing and wrapping applications, wood PVC film empowers manufacturers to deliver premium products efficiently. Whether you are outfitting a luxury hotel in Southeast Asia or manufacturing modular kitchen cabinets for the European market, the consistency and performance of this material ensure project success.

Ready to elevate your production quality?

Contact us today to request your free sample kit and comprehensive product catalog. Our team of technical experts is ready to discuss your specific requirements, offer competitive factory-direct pricing, and provide the tailored solutions you need to stay ahead in the market.

B2B partnership for Wood PVC Film Supply