Table of Contents

Buying PVC film without a solid grasp of how it’s made is a recipe for procurement headaches. The usual suspects? Inconsistent thickness, poor printability, or failing environmental compliance checks. Whether you are sourcing decorative overlays or industrial piping wraps, the integrity of that base film dictates exactly how long your final product lasts.

This guide strips back the layers of industrial PVC production. We’ll walk through the transformation from raw resin to finished rolls via Calendering, Extrusion, and surface finishing. For procurement managers and engineers, knowing these technical workflows is the difference between hoping for quality and engineering it into your supply chain.

1. Raw Material Preparation: The Chemistry Behind the Film

High-quality PVC film isn’t made on the production line; it’s created in the formulation lab. The specific chemical recipe—the compound—decides if that material ends up as a rigid blister pack or a soft, draping tablecloth.

Researching Specific PVC Resin K-Values

The foundation of everything is the PVC resin, specifically its “K-value,” which measures molecular weight. Think of this as the DNA of the film.

- Flexible Film: Manufacturers aim for a K-value of 65 to 70. This higher molecular weight allows the resin to drink up plasticizers efficiently, giving you that rubber-like flexibility and tensile strength.

- Rigid Film: Here, we drop to a K-57 to K-60 range. Lower viscosity resin flows smoother with less heat buildup. That stability is non-negotiable for products like credit card overlays or pipe wraps that need to hold their shape.

Essential Additives and Formulation Percentages

Raw PVC is naturally brittle and hates heat. To make it workable, we introduce additives measured in parts per hundred resin (phr).

- Plasticizers: This is the softener. For flexible uses, DOP or DOTP is added at 25–35 phr. For rigid films? It’s dialed back to 0–5 phr to keep things stiff.

- Heat Stabilizers: PVC burns easily. Calcium-Zinc (Ca-Zn) stabilizers (2–3 phr) are the industry standard to stop the material from yellowing or degrading during extrusion.

- Impact Modifiers: Ingredients like MBS (Methyl Methacrylate Butadiene Styrene) are tossed in at 5–8 phr for semi-rigid films. This stops the plastic from shattering under stress.

Regulatory Compliance Standards for Formulation Safety

In today’s B2B market, chemical safety is just as critical as durability. Top-tier factories screen formulations against REACH SVHC lists to cap phthalates like DEHP. If you are exporting to the EU, RoHS compliance is a must to ensure zero heavy metals (Lead, Cadmium). For the US, Prop 65 compliance is mandatory, requiring specific labeling if DINP content crosses certain thresholds.

The High-Speed Mixing Process

Once the recipe is set, the ingredients hit a two-stage mixing cycle. First, they enter a Hot Mixer, where friction cranks the heat up to 110–130°C. This drives out moisture and forces the resin to absorb the plasticizers. Immediately after, the batch is dumped into a Cold Mixer to snap the temperature back down to 40°C. This cooling step is vital. If the mix stays hot, it degrades or “bridges” in the hopper, causing lumps that ruin the film later on.

Raw PVC resin powder mixing process

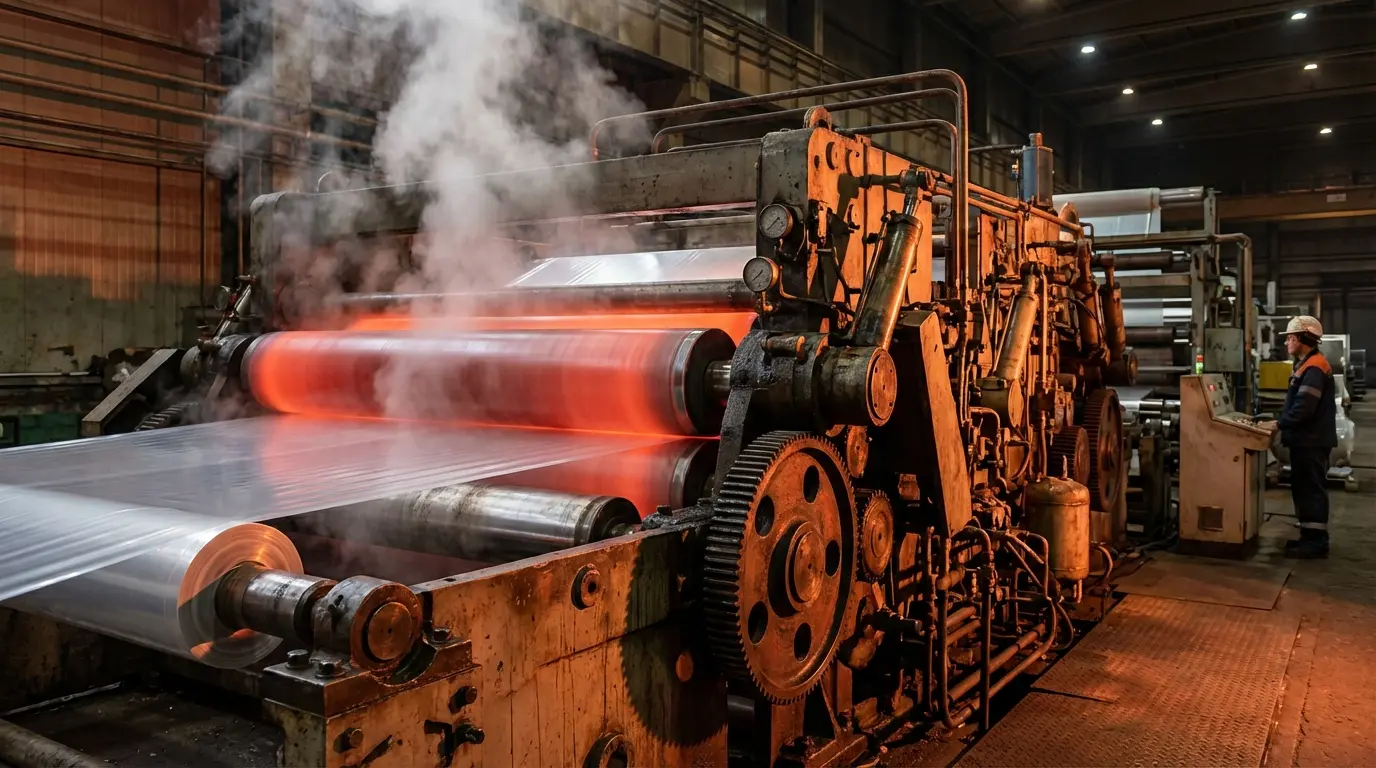

2. The Calendering Process: Mastering Uniformity and Volume

Calendering is the heavy lifter of the PVC industry. It is designed to churn out massive volumes of sheeting between 0.05mm and 1.20mm. The process uses a stack of heated steel rollers to squeeze the plastic into a continuous web.

Operation of Planetary Extruders and Banbury Mixers

Before hitting the rollers, the dry blend needs to become a molten mass. A Planetary Extruder or Banbury Mixer applies immense shear force to “gel” the PVC at roughly 160–190°C. It’s a delicate balance. If the material isn’t fully gelled, you get “fish eyes” (unmelted spots). Overwork it, and the plastic degrades, losing its transparency.

4-Roll vs. 5-Roll Calender Configurations

The roller setup dictates the film’s clarity.

- L-Shape (4-Roll): The standard for general-purpose, opaque films.

- Inverted-L: The go-to for rigid films. Stacking the rollers vertically gives operators better control over the material feed.

- F-Shape (5-Roll): Essential for high-clarity films. That extra roller adds another “nip” point to polish the surface and squeeze out microscopic air bubbles.

Choosing F-shape or Inverted-L configurations is mostly about minimizing air entrapment—critical if you need optical clarity for medical or packaging uses.

Standard Thickness Tolerance

Precision separates the average factories from the elite. Modern lines with automatic gauge controls hit tolerances of ±0.01mm. For high-stakes applications—like overlay films under 0.10mm—advanced gear can tighten that to ±0.005mm. When your converting lines are automated, even a single micron of variance can cause a jam.

The Role of the ‘Accumulating Stock’ (Bank)

Between each roller set, you’ll see a rolling sausage of material called the “bank.” It’s not just excess; it’s a functional part of the process. The bank rotates constantly to mix the material, ensuring the temperature and density stay uniform while pushing air bubbles out. Operators watch this like hawks. Too small, the film thins out. Too large, the surface cools too fast, leaving flow lines.

PVC film calendering rollers in operation

3. Extrusion and Blowing: Methods for Specialized Applications

Calendering wins on volume, but extrusion and blowing take the lead when you need unique physical properties or ultra-thin gauges.

Cast Film Extrusion vs. Calendering

Cast Film Extrusion pushes molten PVC through a flat die onto a chilled roller. Unlike calendering, which physically stresses the material, cast extrusion creates a film with almost zero internal tension or “memory.”

- Speed: Slower than calendering, but the optical clarity is unmatched.

- Thickness: Perfect for very thin films (0.025mm – 0.10mm) with tight tolerances (±0.002mm).

- Use Case: This is the preferred method for premium vehicle wraps. Because the film has no stress, it won’t shrink back after installation.

The Blown Film Process (Bubble Method)

For things like food-grade cling film, manufacturers use the Blown Film process. The melt is extruded through a circular die and inflated with air, creating a massive plastic bubble. This stretches the molecules in two directions (Machine and Transverse), making the film incredibly tough despite being thin (0.01mm – 0.05mm). The bubble is collapsed and wound up, creating the efficient shrink films used in packaging.

T-Die Extrusion for Thick Sheets

When specs exceed calendering limits (usually >0.5mm up to 30mm), factories switch to T-Die Extrusion. It’s similar to casting but uses a wider die gap. This is standard for heavy-duty chemical tank liners or construction barriers. The T-Die ensures the heavy material flows evenly across the full width, keeping the profile flat enough for welding.

Blown film extrusion bubble process

4. Surface Treatment and Lamination: Adding Functional Value

Raw PVC film rarely comes off the line ready for the end-user. Surface treatments—applied inline or offline—turn plain plastic into functional material.

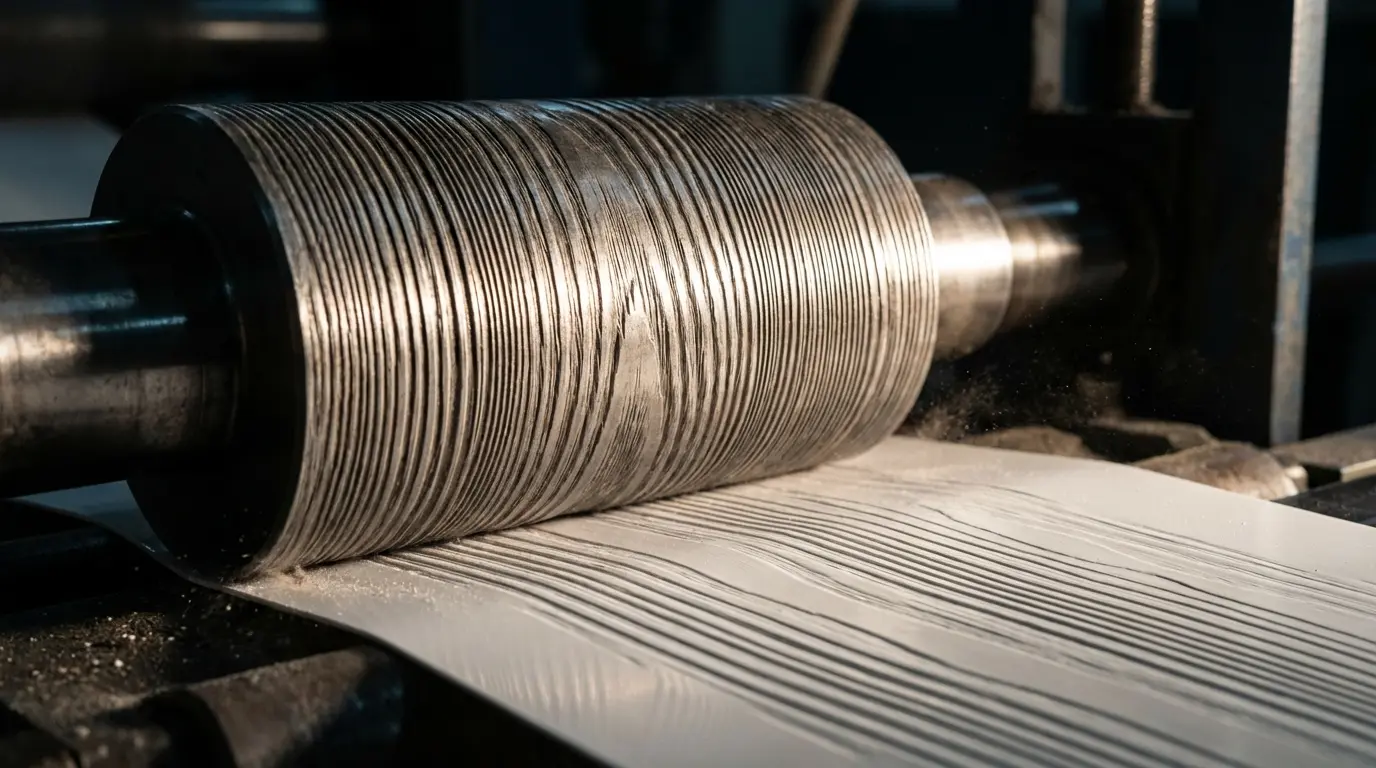

Embossing Rollers and Texture Retention

Creating wood grain, matte, or leather finishes involves passing the film between a steel embossing roller and a rubber backing roller. The secret is temperature shock. The film is heated to 160°C to soften it, while the embossing roller is chilled to 20–50°C. This “freezes” the pattern instantly. If the roller is too warm, the plastic relaxes, and the texture fades.

Corona Treatment for Printability

PVC is naturally non-porous; ink hates it. Corona Treatment blasts the surface with high-voltage electricity to oxidize it, raising the surface energy so ink can bond.

- Solvent Inks: Need a surface energy of 38–40 Dyne/cm.

- UV Inks: Demand a higher level, around 40–50 Dyne/cm.

If you skip this or get the levels wrong, the ink will bead up or peel off later.

UV Coating and Annealing

For outdoor projects like window profiles, films get a UV coating and an annealing bath. The coating blocks radiation to stop fading. Annealing—heating the film and cooling it slowly—relieves internal stress. This ensures the film won’t warp or shrink when the sun beats down on a building facade.

PVC film embossing process detail

5. Manufacturing Excellence & Quality Control (QC)

Reliability in B2B supply chains comes down to consistent QC. The best factories bake testing protocols directly into the production line.

ASTM/ISO Testing Protocols

Physical properties need to match international standards. ASTM D882 is the benchmark for Tensile Strength and Elongation at Break. This verifies that the film can handle stretching during installation without snapping. For packaging, ASTM D2732 checks shrinkage rates to guarantee the material behaves predictably in heat tunnels.

Online CCD Visual Inspection Systems

Manual checks don’t work when lines run at 100 meters per minute. Factories now use CCD (Charge-Coupled Device) Vision Systems. These cameras scan 100% of the web, spotting defects like black spots, gels, or contamination down to 0.1mm. The system flags the exact location so operators can splice out the bad section before shipping.

Checklist for Flatness and Camber

For clients using automatic wrapping machines, “runnability” is everything. QC technicians monitor:

- Camber (Bow): Curvature must be under 0.6mm per 300mm. Too much bow, and the film wrinkles or tracks off the machine.

- Flatness: No “baggy” spots or tight centers.

- Twist: Must stay under 0.5 degrees per 300mm.

Traceability Systems

If a quality dispute arises, traceability is your safety net. Leading plants use automated batch coding. Every roll gets a unique ID linked to the production time, the specific machine, and the exact batch of resin used. This granularity allows for rapid root-cause analysis.

PVC film tensile strength testing

6. Sustainable Manufacturing and Waste Management

Modern PVC production is shifting toward a circular economy, focusing on minimizing waste and cutting energy use.

Incorporating Recycled PVC

We can now include Recycled PVC (PCR or PIR) without sacrificing performance. Using co-extrusion, factories can sandwich up to 30% recycled content in the middle layer of a film, capping it with virgin resin on top and bottom. You get the same aesthetic finish and surface durability, but with a significantly lower carbon footprint.

Exhaust Gas Treatment (VOCs)

Heating plasticizers releases Volatile Organic Compounds (VOCs). Responsible plants run Electrostatic Precipitators (ESP) to catch oil mists, followed by Activated Carbon filters. These systems hit filtration efficiencies of >95%, ensuring exhaust air meets safety standards and preventing odor pollution.

Energy Efficiency in Cooling

Cooling massive calender rolls takes a lot of power. Factories are moving to closed-loop water systems. By recycling cooling water and using heat exchangers to capture thermal energy for other stages, plants drastically cut energy consumption—which helps stabilize costs for buyers.

Industrial exhaust filtration system

Frequently Asked Questions (FAQ)

Q1: What is the minimum production quantity (MOQ) for a custom formulation?

For standard clear or white films, the MOQ sits around 1,000 m (1km). If you need custom colors or specific additives (like UV stabilizers or fire retardants), that usually jumps to 3,000 m (3 km). The internal mixer and extruder simply need that minimum volume to achieve a stable melt.

Q2: How does Medical Grade PVC manufacturing differ from Industrial Grade?

Medical Grade PVC is produced in an ISO Class 5 Cleanroom to stop particulate contamination. The formula strictly uses non-DEHP plasticizers (like Citrates or TOTM) and aligns with FDA 21 CFR standards. Industrial films don’t need cleanrooms and might use standard phthalates where regulations allow.

Q3: Can you control the shrinkage rate for packaging films?

Yes. Shrinkage is dictated by tension. High tension during cooling locks in “memory,” causing the film to shrink when reheated (great for shrink wrap). Annealing (slow cooling) relaxes the molecules, creating a stable film that won’t shrink.

Q4: What are the visual signs of poor manufacturing quality?

Look for “telescoping” (misaligned layers on the roll), noticeable color shifts between batches, visible “fish eyes” (unmelted gel spots), or thickness variations you can feel by hand.

Conclusion

Producing PVC film is a balancing act between heavy engineering and precise chemistry. The quality of the final roll is decided by everything from the K-value of the resin to the pressure of the calendering rolls and the shock-cooling of surface treatments.

For B2B buyers, understanding these mechanics is the best way to mitigate risk. Whether you need the cost-efficiency of calendering or the flawless clarity of cast extrusion, knowing the “how” empowers you to demand the best “what.”

Need a manufacturer that guarantees precise gauge control and custom formulations? Contact our engineering team today for a free sample kit tailored to your specs. We provide factory-direct pricing and the technical backing to ensure your material performs exactly as needed.